High-Tech Manufacturing Careers Begin at Lakeshore College

Cheers to Celebrating National Manufacturing Month

October 22, 2025 -

The image of manufacturing for some people brings up images of grimy factories filled with the clatter of machinery and workers carrying out labor-intensive processes. However, modern manufacturing has undergone a dramatic transformation, evolving into a sleek, technologically driven powerhouse.

As we wind down National Manufacturing Month, we’d like to share with you just how valuable modern manufacturing is to our Lakeshore community and the important connection our college has to it.

Today’s increasingly automated factories are using cutting-edge technologies. They require a highly skilled workforce able to design, manufacture, program, set up, run, fix, and maintain all the technology.

This is where Lakeshore College steps in, providing the critical training and education needed by our local manufacturing workforce. This fall, we have:

719 students aged 16 to 71 enrolled in 21 manufacturing-focused programs

Top program enrollments are Intro to Electro Mechanical Technology, Welding-Industrial, and Intro to Maintenance Mechanic.

Manufacturing Is Our Local Powerhouse

Lightcast Q3 2025 data shows manufacturing is the largest industry in our district, making it the powerhouse of our economy.

The sector provides over 33,000 jobs—a staggering 32% of Lakeshore’s local workforce.

Manufacturing offers very competitive wages, averaging $88,537 annually. That’s an impressive wage considering the median Wisconsin household income sits at $77,488 according to the U.S. Census Bureau.

With the rapid evolution of manufacturing technology, a skills gap has emerged, and many more trained workers are needed.

Manufacturing Requires a Highly Skilled Workforce

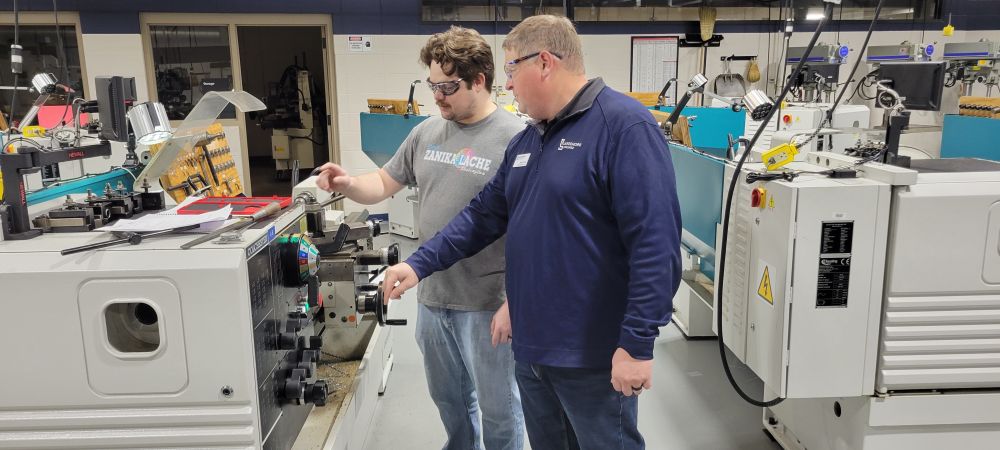

In Lakeshore's KOHLER Center for Manufacturing Excellence, students learn and upskill in our state-of-the-art classrooms and labs dedicated to welding and fabrication, industrial electricity, robotics, mechanical design, precision machining, and other manufacturing-focused skills.

While automation takes on repetitive tasks, trained individuals are increasingly needed in higher-level roles such as design, innovation, and problem-solving.

In addition, even in a high-tech environment, success requires workers to have soft skills such as the ability to communicate clearly, work well with others, be dependable, and able to adapt to changing situations. Lakeshore instructors ensure students learn those skills, too.

“I enjoy teaching not only technical skills and knowledge but also the soft skills individuals of all ages need to succeed in the increasingly sophisticated manufacturing workplace,” says Mark Lorier, CNC/Machine Tool Instructor.

Educators & Businesses Work Together

Due in part to increased collaboration over the last several years between educators and businesses, numerous high schools are investing in state-of-the-art manufacturing equipment. This presents a fantastic opportunity to initiate skilled training for future generations.

On top of the ability to gain in-demand, high-tech skills right at their schools, students benefit from Lakeshore’s college-level courses available at their schools, enabling them to earn credits simultaneously for both college and high school. This semester, 130 students in 18 local high schools are taking manufacturing courses. Getting that jump start in high school can lead to getting into the workforce sooner.

An Aging Welding Workforce Requires Replacements

This fall, Lakeshore’s welding programs have almost 200 enrollments. In addition, welding courses are offered at 14 local high schools. Welding is among the most popular skills our students want to learn, which is good news.

According to the American Welding Society, 21.4% of current welders are age 55 or older, meaning over 157,000 are approaching retirement. Combine that with industry growth and the association predicts 320,500 new welding professionals will be needed in the U.S. by 2029.

Dave Saunders, Lakeshore’s Weld Instructor/Weld Program Coordinator, is well aware of the current shortage locally. “The demand for our welding students here at Lakeshore College remains high. It doesn’t matter if they graduated or are still in the program, local industry needs trained personnel to fill their positions,” he says.

To meet local needs among employers to get their welders certified by the American Welding Society (AWS), Lakeshore serves as an AWS accredited welding test facility. Our location is much more convenient and saves employers money they previously spent sending welders several hours away for certification. Since becoming accredited in 2020, we’ve granted 725 AWS certifications and AWS welder qualifications to welders from Wisconsin and other states.

Apprenticeships Offer “Earn While You Learn” Experiences

A growing number of high school students are choosing to explore manufacturing through Youth Apprenticeships. These hands-on, paid employment experiences provide students with practical applications of what they learn in class. Youth Apprenticeship is a proven talent-acquisition strategy employers can use to build their own workforce pipelines and shape their workforce of the future.

Having worked closely with numerous students involved in Youth Apprenticeship programs, Lorier says he has witnessed how Youth Apprenticeships foster a meaningful connection between course material and real-world experiences. He says it also opens up further learning opportunities since students often feel motivated to talk about their workplace activities.

Upon graduating high school, some students work with their employer to transition into a Registered Apprenticeship, where they receive ongoing paid training in practical on-the-job settings while taking Lakeshore College courses.

With strong support from local employers, Lakeshore is providing instruction for 196 Registered Apprenticeship students this fall. Current apprenticeship programs include:

- Industrial Electrician

- Machinist

- Maintenance Mechanic/Millwright

- Maintenance Technician

- Tool & Die

Leading with Competency-Based Education

After Lakeshore’s leadership team realized our traditional schedules were barriers to potential students who were working and/or had family commitments, we started exploring the competency-based education (CBE) model—a delivery model growing in use around the country. We found CBE provides the flexibility students need so college can fit around their work and personal commitments.

Lakeshore, considered a state and national leader in the delivery of competency-based education, began offering programs in the model in 2020. We currently offer 39 programs through CBE, which is over 50% of our offerings.

Almost a third of our CBE programs are manufacturing-focused, which has led to increased enrollments, which should over time help fill skills gaps among employers.

“Data shows more students are shifting to part-time learning, and we’re seeing that here at Lakeshore. There are many reasons why, however, the most common one I hear from my students is that they can’t afford to take off work. By shifting to CBE, we’re making it possible for students to schedule learning around their work schedules,” says Saunders.

Upskilling Is Cost Efficient

Many employers are investing more into upskilling these days so they can develop their current workers for future needs more cost efficiently than seeking new candidates. To meet the wide variety of training needs among industry, Lakeshore offers multiple opportunities to learn on and off our campus. In addition to short-term certificates, technical diplomas and associate degrees, we offer:

- Advanced Manufacturing Mobile Lab: This lab allows us to bring Industry 4.0 technologies directly to businesses, schools, and community locations, making it convenient to train and upskill individuals.

- Customized Training: We partner with local manufacturers and tailor programs to meet their specific needs.

- Seminars & Continuing Education: These sessions can quickly elevate knowledge and expertise.

- Ed2go: Our partnership with this leading nationwide provider of adult online non-credit education expands learning opportunities across in-demand industries.

Graduates Help Fill the Skills Gap

Lakeshore College is, and will continue to be, a key force in helping close the manufacturing skills gap by training students for well-paying, rewarding careers with local manufacturers. We graduated 285 students in manufacturing programs from 2022-23 through 2024-25, and look forward to graduating at least 100 more this academic year.

Want to Be Part of the Solution?

If you're Interested in learning how we can work together to help fill that skills gap, contact us at registration@lakeshore.edu, 920.693.1366, or explore your career options at: